Repair & rewind services

- alfanar Technical Services (ATS), is a prominent provider of high-quality, precision-engineered repair and rewind services for all types of medium and high voltage static and rotating equipment like Transformers, Motors and Generators.

- Equipped with the most modern machineries and Testing Facilities that conform to International standards, ATS has a competitive edge in repair services

Transformer Rewinding, Repairing and Overhauling

- 231V up to 230kV, ratings from 150kVA up to 200MVA (rewind and repairing).

- 231V up to 380kV, up to 227MVA (overhauling service).

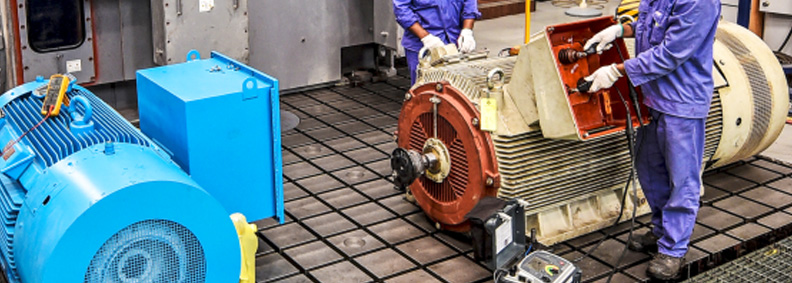

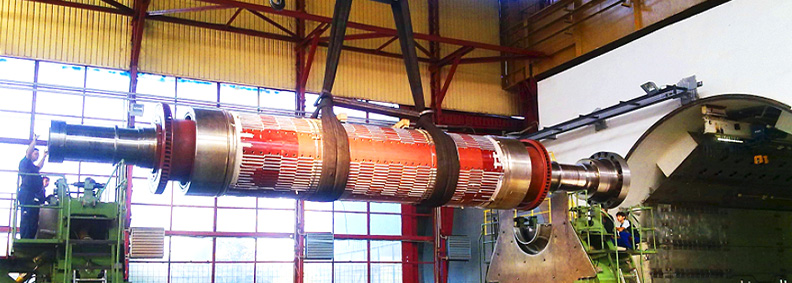

Rotating Machine Rewinding, Repairing and Overhauling

Motors for 380V up to 13.8kV, horse power ratings from 0.5HP up to 27000HP

Generators for 220v up to 24kv with MW Ratings From:

- 2,500KW to 1,200MW for stator

- 4,160KW to 600MW for rotor

Site Services

Our site services for Motors, Transformers & Generators include, site testing, Installation and commissioning, Life assessment studies and site overhauling.

Conductor (magnet wire) manufacturing

Manufacturing of round enamelled, fine, medium, thick wires ranging from 0.2mm to 5.5mm and rectangular wires from 3mm2 up to 80mm2 according to IEC specifications.

Preformed Coil Manufacturing

ATS is a pioneer since 2001 to manufacture coils for Electric Induction motors using various types of insulation like Mica, Resin poor/rich, Kapton.

Vapor phase drying plant

VPD is used in drying of cellulosic insulation of the transformer winding which requires that the moisture content be brought to 5 ppm levels before impregnation of the winding with transformer oil, recovery of the oil and discarding the moisture. The fluid basically acts as a heat carrier to the insulation.

Repair & retrofit

Power transformers are vital to ensure a troublefree supply of power with no interruptions. Whether your transformer has failed or you are planning timely corrective maintenance our team of experts is available for short-term and long-term repairs.

alfanar Technical Services performs the repair, overhaul, and modernization of your power transformers that are performed in our dedicated repair shop.

Motor test facility

- We have one of the most advanced and sophisticated testing facilities in the Middle East region for Motors. Our highly experienced Engineers and skilled technicians successfully contribute in diagnosing the electrical and mechanical fault in the motors

- Motors are tested at no load as per IEC 60034 standards and vibration values are maintained as per IEC 600816 standards. The test plant is capable to test the motors up to 20MW on no load from 1.1KV to 13.8Kv range of motors

Generator assessment process

The life of a generator is mainly dependent on the life of its insulation. Therefore the aging process of the generator has to be very closely monitored. Just like the pulse rate, the blood pressure, sugar level etc., of a human are indicative of his health condition, the capacitance, leakage current, dissipation factor, polarization index, surge voltage with standing strength and partial discharge factors are indicative of the insulation condition of an electric rotating machine.